24 Oct The Short Life of Neon-Cotton

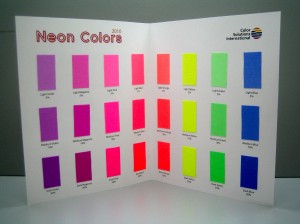

Available products for cotton

There are limited ways to dye cotton with neon colors. Only yellow is available as a reactive dye for cotton. When mixed with other non-neon shades, the neon effect becomes weaker or vanishes although fluorescent lime green shades can be achieved by incorporating a small bright turquoise shading component. Fluorescent colors on cotton can also be achieved by dyeing pre-treated garments with basic dyes. However, these products appear to be only a tiny part of the market.

Neon-Pigments on Cotton

Therefore the current trend is to use neon-pigments on cotton rather than dyes. Pigments on cotton look great and offer a wider color palette. However they also involve higher costs and effort in the application process, and there are limitations with the quality in respect of color fastness.

Sourcing and Application

Your standard pigment vendor will most likely not sell neon-pigments, but it is possible to buy them from specialized vendors. Global vendors are rare though, which makes a global color communication process harder (I will get to that later).

There are only a limited number of processes available to apply neon-pigments. The most common ones are the padding application with a binder for woven fabrics, and the exhaust method using a cationic pretreatment which is used on garments. This can limit the fabric constructions that are suitable for coloring with fluorescent pigments.

Many dye houses are reluctant about using fluorescent pigments. It involves a higher contamination risk which would result in additional clean-up time of the equipment and therefore higher costs. As a result, there are not many dye-houses available for this process. You will find specialized manufacturers, but the application costs will be higher. Of course, with a continuing trend of using pigments, there will be more dye-houses available particularly those involved in garment dyeing.

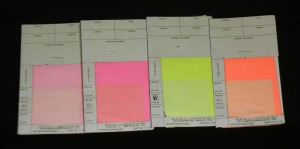

Accurate Color

The color communication process is less controllable for neon-pigments as spectrophotometers cannot read fluorescent colors accurately. Therefore, only a visual reference can be provided but no certified color standards with accompanying spectral data. The application methods are repeatable, but a wider shade tolerance should be expected as only visual control can be used which leads to less consistent colors.

Color Fastness

Last but not least, there are some limitations with the fastness of the end product that you need to consider when using neon-pigments. They have a low lightfastness. The 20-hour AATCC light fastness test shows ratings between 1 and 2.

The pigments are heat sensitive, so they may become dull or change shade if exposed to heat. But to achieve adequate wash-fastness, the binder incorporating the pigment has to be appropriately cured in the production process. The dyeing/finishing operation needs to find the right temperature so as not to alter the color and to achieve maximum wash fastness. By applying heat for a more extended period in the production process, a better wash-fastness can be achieved. Your pigment vendor should be able to advise you. However, in the end, the neon-pigments have a lower wash-fastness than reactive dyes which are generally used for coloration of cotton.

I hope that this information will help you when dealing with neon colors on cotton. As an alternative to neon-colors, there are incredibly bright dyes for cotton available but without the fluorescent effect. The higher fastness reactive dyes might still be an excellent alternative to limited fastness neon-pigments.

What are your experiences with neon-colors? Do you think strong Neon pigment shades are here to stay or will they soften to bright pastels next season?

Related topics:

*This blog post is written by a member of our expert blogging community and expresses that expert’s views alone.